The resistance to fading capability of thermal printing fabric can vary depending on several factors, including the type of thermal printing technology, the quality of the thermal transfer ribbon or material used, and the environmental conditions to which the fabric is exposed. Here are some considerations regarding the resistance to fading in thermal printing fabric:

Heat-Set Images: Thermal printing fabric relies on heat to create images on the fabric. The heat activates the dyes or pigments in the thermal transfer ribbon, which are then transferred to the fabric. Heat-set images tend to be more resistant to fading compared to some ink-based printing methods, which may use water-based inks that can be more susceptible to fading when exposed to moisture or UV light.

Thermal Transfer Ribbon Quality: The quality of the thermal transfer ribbon or material used plays a significant role in fading resistance. High-quality ribbons often contain durable dyes or pigments that are less likely to fade over time. Specialty ribbons designed for outdoor or industrial applications may offer enhanced resistance to fading.

UV Exposure: Ultraviolet (UV) exposure from sunlight and artificial light sources can cause fading in printed materials, including thermal printing fabric. The level of UV resistance can depend on the type of dyes or pigments used in the ribbon and any UV-absorbing or blocking coatings applied to the fabric.

Environmental Conditions: The resistance to fading can be influenced by environmental factors such as humidity, temperature, and pollution. Fabrics exposed to harsh outdoor conditions or industrial environments may experience faster fading if not adequately protected.

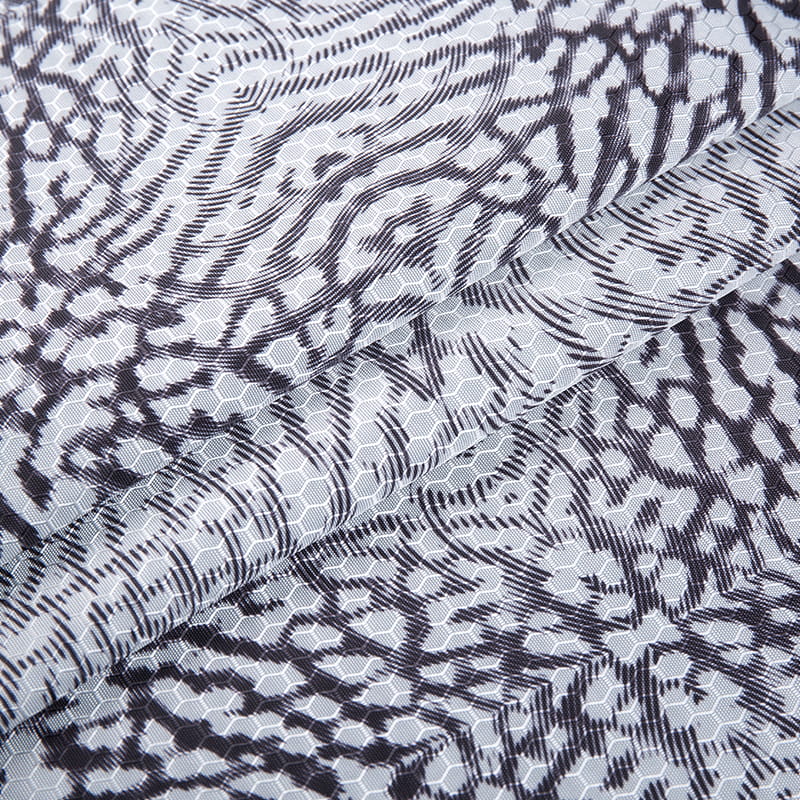

Fabric Material: The type of fabric material used can affect fading resistance. Some fabrics are inherently more resistant to fading than others. For example, synthetic fabrics like polyester may offer better resistance to fading compared to natural fibers like cotton.

Coatings and Treatments: In certain applications, additional coatings or treatments may be applied to thermal printing fabric to enhance its resistance to fading. UV-resistant coatings or laminates can help protect the printed images from UV radiation.

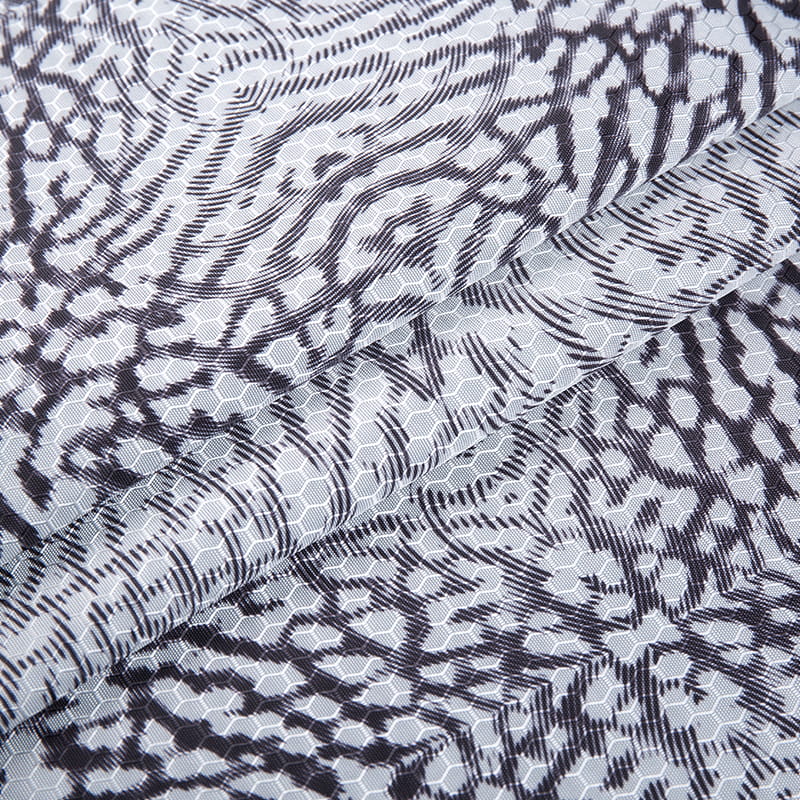

Printing Quality: The quality of the printing process itself, including factors like temperature control and pressure during the thermal printing process, can impact the longevity of the printed images and their resistance to fading.

English

English Español

Español