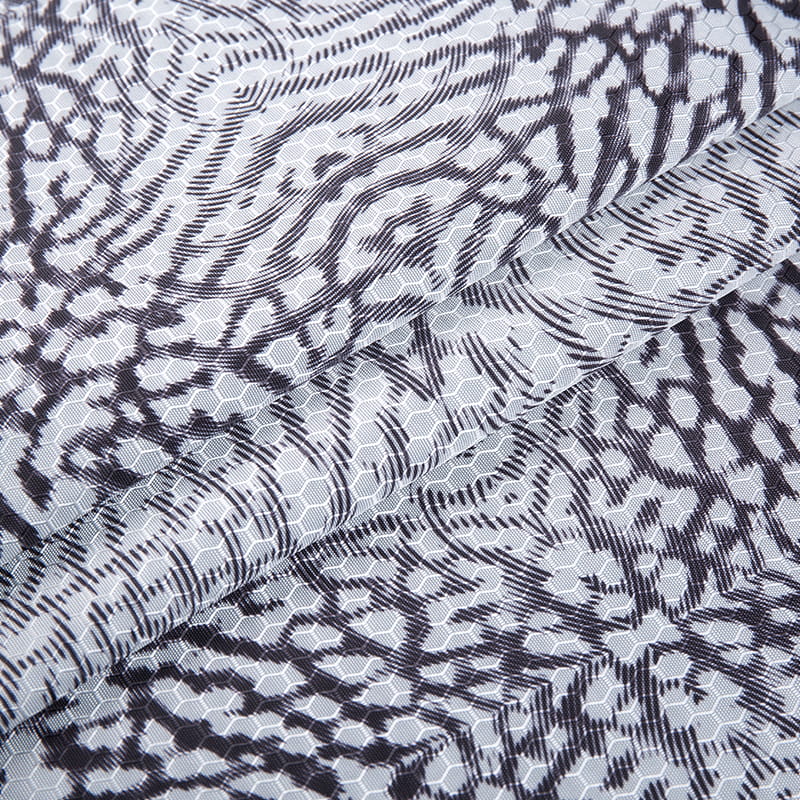

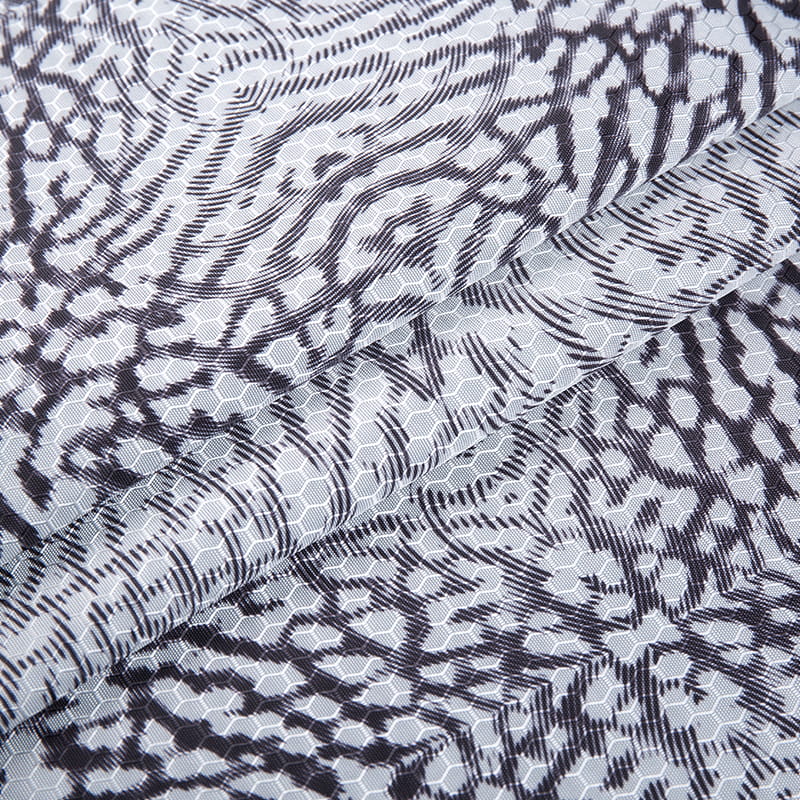

Ultraviolet (UV) radiation can have several effects on thermal printing fabric, depending on the materials used and the level of UV exposure. Here are some of the effects of UV radiation on thermal printing fabric:

Fading: UV radiation is a significant cause of fading in printed materials, including thermal printing fabric. Over time, exposure to UV rays, whether from sunlight or artificial light sources, can break down the dyes or pigments in the printed images. This can result in a gradual loss of color vibrancy and clarity in the thermal prints.

Color Shift: UV radiation can cause a color shift in thermal prints. Colors that were once vibrant and true may shift towards a different hue or become less saturated due to the chemical reactions induced by UV exposure.

Image Degradation: Prolonged exposure to UV radiation can lead to image degradation in thermal prints. This can include the blurring or loss of fine details in the printed images and a decrease in overall print quality.

Reduced Longevity: UV exposure can reduce the longevity of thermal prints. Prints that are exposed to significant UV radiation may deteriorate more quickly, and their visual appeal may diminish over time.

Material Weakening: UV radiation can also weaken the fabric itself, especially if the fabric is not UV-resistant. Over time, exposure to UV rays can lead to material degradation, which may result in reduced fabric strength and durability.

To mitigate the effects of UV radiation on thermal printing fabric, various strategies can be employed:

UV-Resistant Coatings: Applying UV-resistant coatings or laminates to the thermal printing fabric can help protect the printed images from UV radiation. These coatings act as a barrier and can significantly slow down the fading process.

UV-Resistant Inks: When selecting thermal transfer ribbons or materials, consider using UV-resistant inks or pigments. These inks are formulated to better withstand UV exposure and maintain color stability.

Shade and Protection: Keeping thermal printing fabric out of direct sunlight or providing shade can reduce the intensity of UV exposure. For outdoor applications, using UV-protective coverings or enclosures can help protect the fabric.

Indoor Use: If possible, using thermal printing fabric in indoor environments with controlled lighting can help minimize UV exposure.

Regular Maintenance: Periodic inspection and maintenance of thermal prints and fabric can help detect signs of fading or deterioration early, allowing for timely corrective actions.

It's essential to consider the specific application and environmental conditions when using thermal printing fabric. For applications where UV resistance is crucial, choosing the right materials, coatings, and protective measures can help prolong the life and visual quality of the printed images.

English

English Español

Español